A multitask modelling framework for tablet manufacturability and quality attributes in direct compression using knowledge-guided neural networks

October 27, 2025

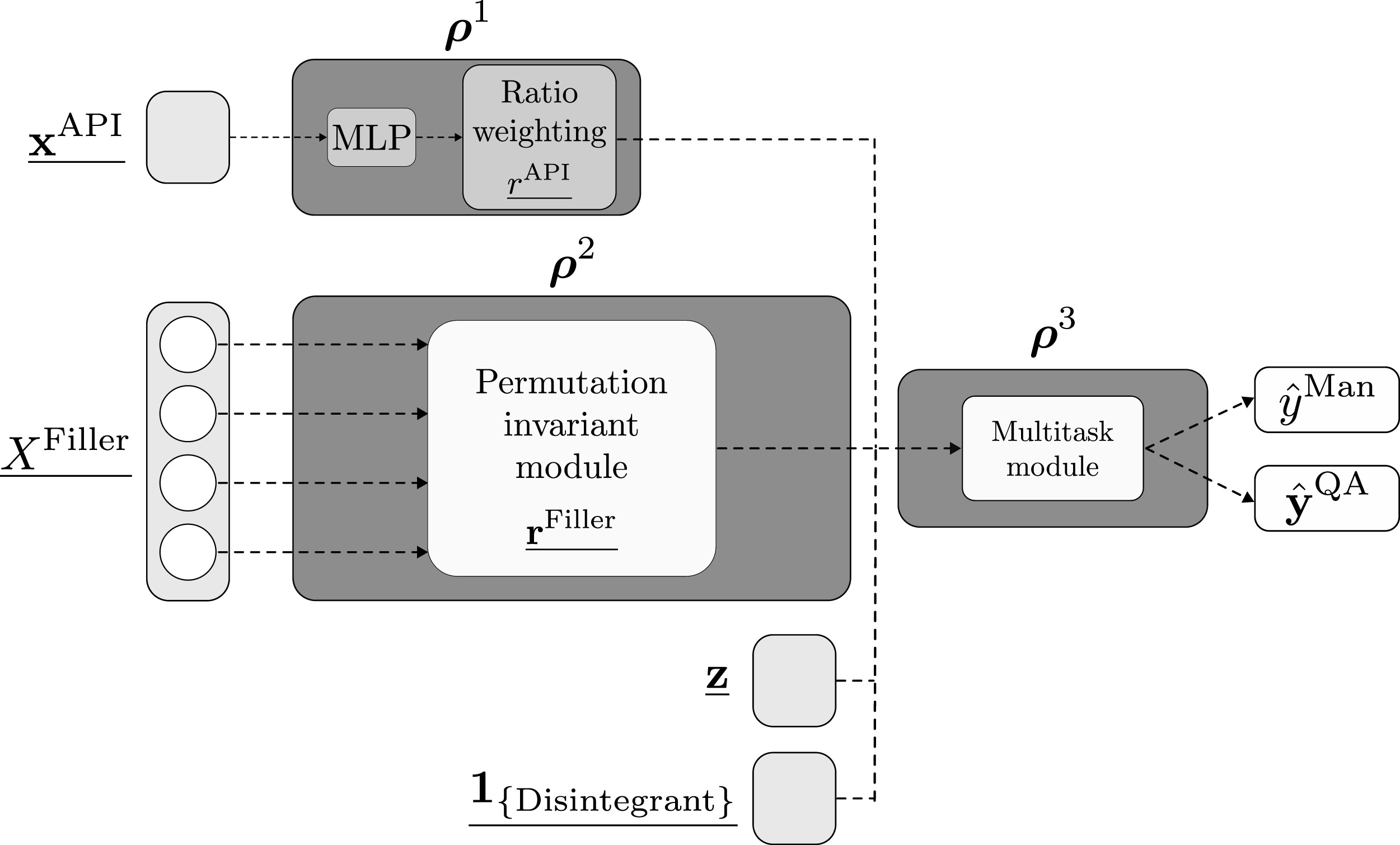

Assessing the feasibility of a manufacturing route for a given formulation and process is a key initial step in drug product development. Additionally, the final product must meet a series of critical quality attributes to be considered suitable to market. However, modelling approaches traditionally focus on either assessing the manufacturability of a given formulation and process, or modelling tablet quality attributes, but seldom on both aspects together, even though the two are closely linked. Therefore, this work proposes a joint modelling framework using neural networks that allows for estimation of both manufacturability of a formulation in direct compression and its quality attributes. The model input is the properties of the raw materials that make up the formulation, the blending ratios, and the processing conditions used during direct compression. Different methods to model interactions between properties of the materials that make up the formulation are assessed, including attention mechanisms. Additionally it is shown how expert knowledge can be embedded into such model by means of the implementation of monotonicity rules between specific inputs and the outputs. The results show that a joint modelling framework of both tasks can be leveraged given the inherent relationship between both tasks. The proposed methodology aims to assist formulation scientists in accelerating formulation and process development.